Bceopt - boiler Control efficiency optimization system

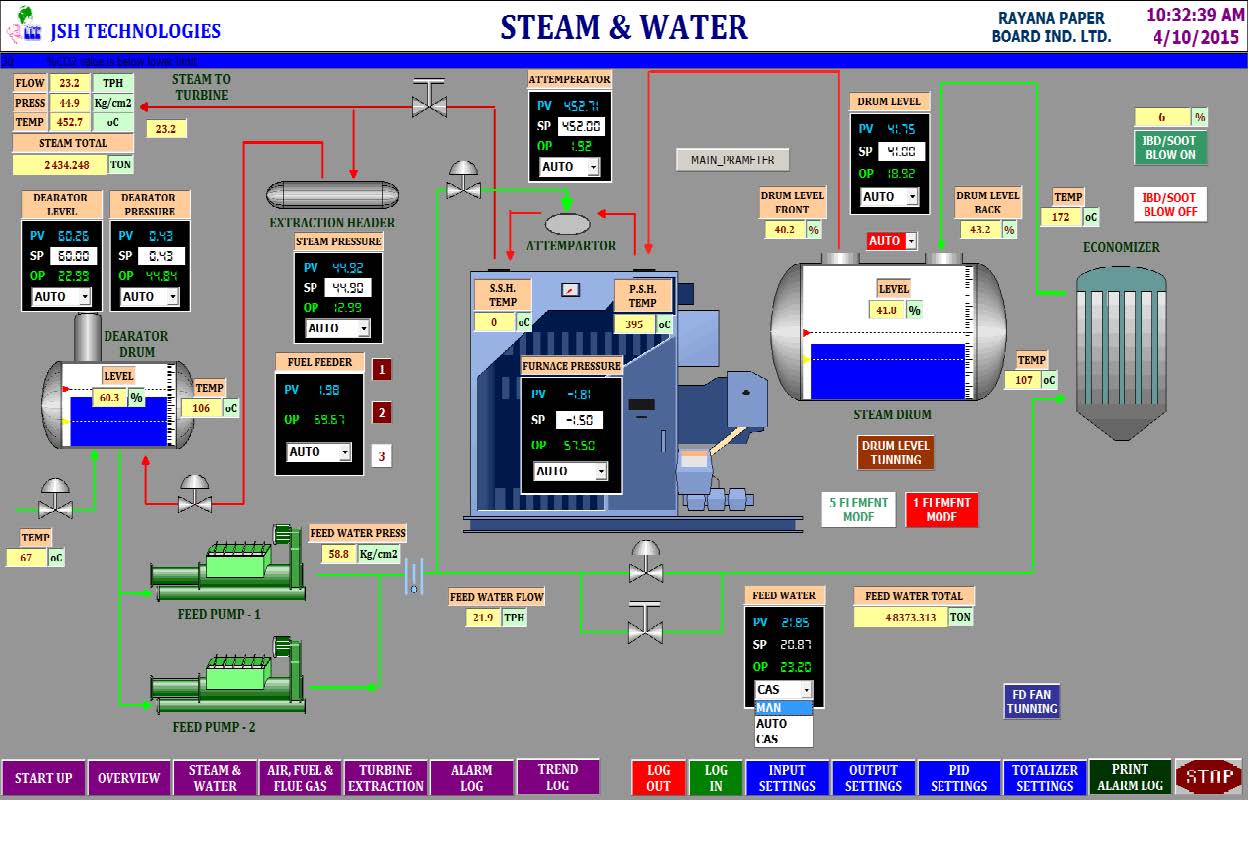

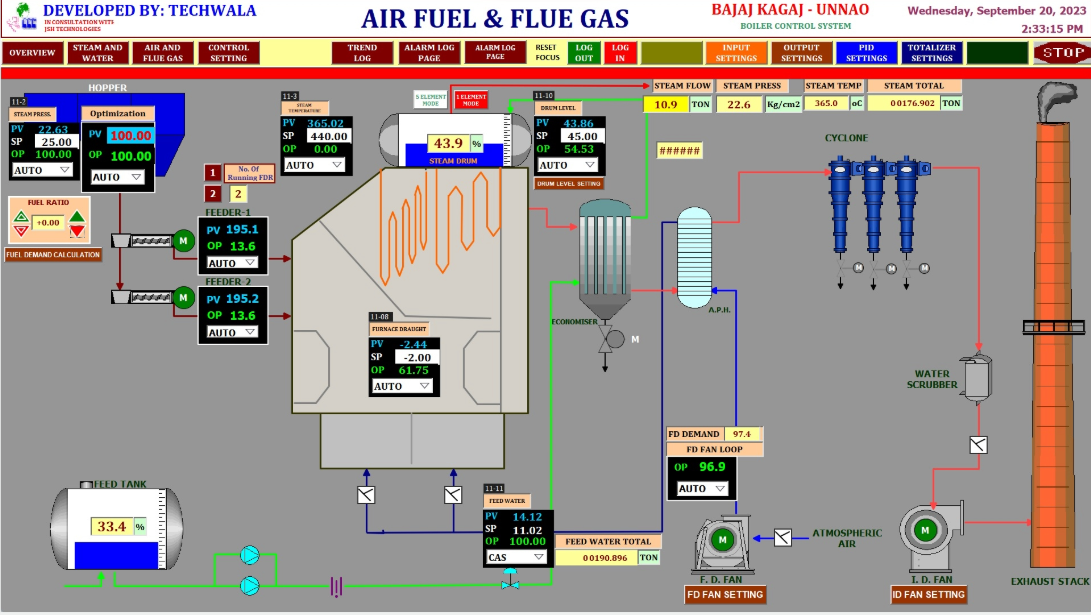

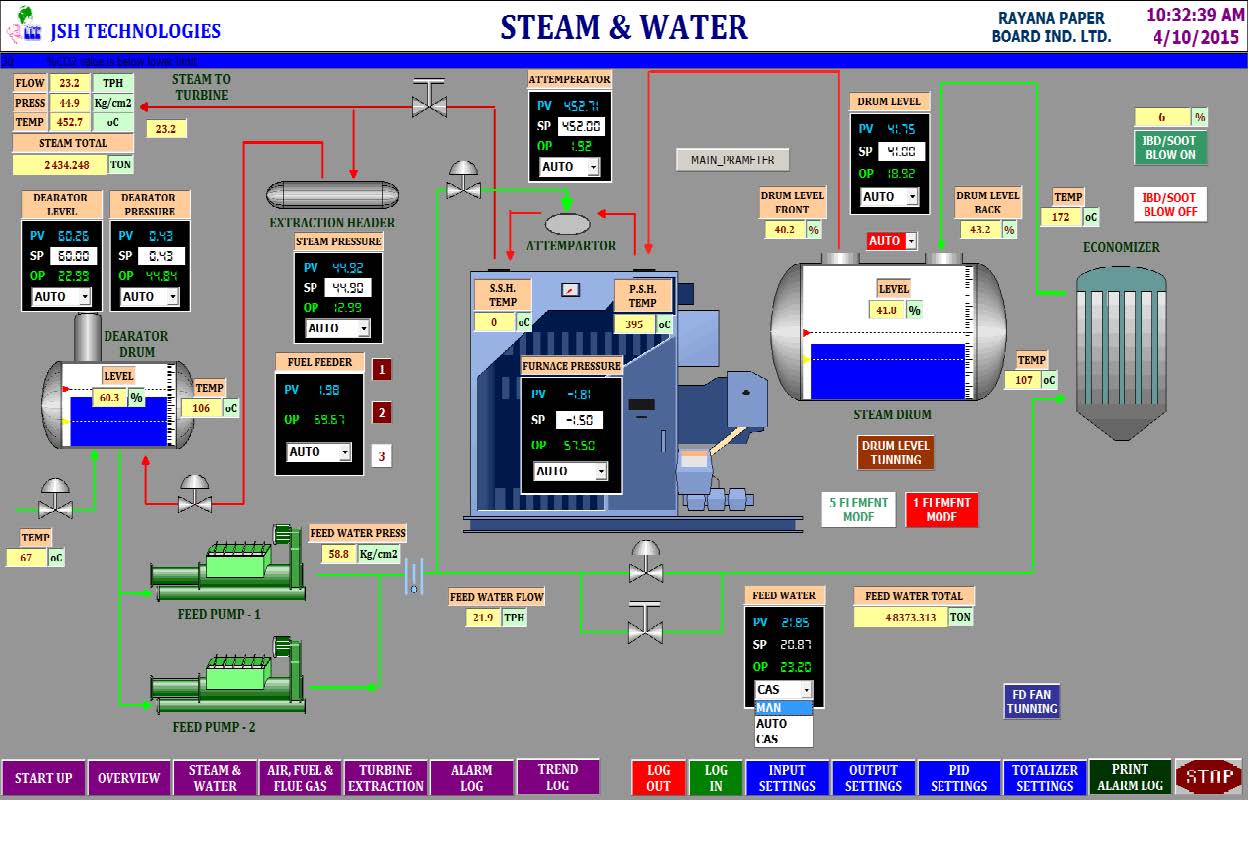

BCEOPT- (Boiler Combustion Efficiency Optimization & Performance Tracking) is an intelligent control and monitoring solution aimed at maximizing boiler efficiency, reducing Fuel usage, and lowering emissions. It integrates advanced algorithms, real-time data analysis, and automated control to ensure stable operation, optimize performance, and support cost-effective, reliable, and environmentally sustainable power plant operations.

Concept

- Optimizes boiler fuel-to-air ratio for consistent combustion efficiency

- Continuously monitors key parameters to maintain stable boiler operation

- Minimizes emissions by controlling excess air in the combustion process

- Enhances equipment life by reducing thermal and mechanical stress

- Provides actionable reports supporting predictive maintenance and cost efficiency

Combustion Control

- Uses Model-Based Predictive Control (MPC) instead of traditional pressure- or load-based fuel control.

- Eliminates need for Load-vs-Fuel graphs and manual Fuel-to-Air ratio adjustments.

- Continuously evaluates Boiler parameters against a predictive model for optimal control.

- Regulates Air feeding based on Load, Fuel needs, and O₂ measurement.

- Achieves 1.0–1.5% fuel savings with full combustion control implementation.

Drum Level Control – VFD Feed Pump

- Outlet Pressure Control – Maintains pump outlet pressure via VFDs; efficient at full load but less so at part load, increases maintenance.

- 3-Element Control without Valve – Direct pump flow control; saves energy but raises pump wear risk.

- Saving Potential – 25 TPH pump at reduced pressure can save ~40,000/month.

- Structural Resonance Risk – VFDs speed variations may cause vibrations, damaging pumps and piping.

- Rotor Dynamics Issue – Speeds near critical points can cause excessive vibration and mechanical stress.

5-Element VPC Control

- Stable drum level in varying load conditions

- Reduced maintenance requirements

- Additional energy savings

Combines valve-based control with VFDs control. The drum level is maintained via the 5-element loop while the VFDs optimizes pump speed.

Benefits:

BENEFIT

- Enhanced Boiler efficiency via Multi-Parameter Monitoring

- Stabilizes Pressure and Flow with advanced controls, reducing wear, lowering maintenances costs, and extending Boiler life.

- Ensures stable Steam Pressure and Temperature with advanced controls, delivering consistent quality fewer interruption, and improved process reliability.

- Optimize Fuel-air controls to cut emissions, ensure compliance, and support sustainable, eco-friendly operations.

- Significant Fuel Cost Savings through Advanced Combustion Control.

"Smarter Control, Better Performance."