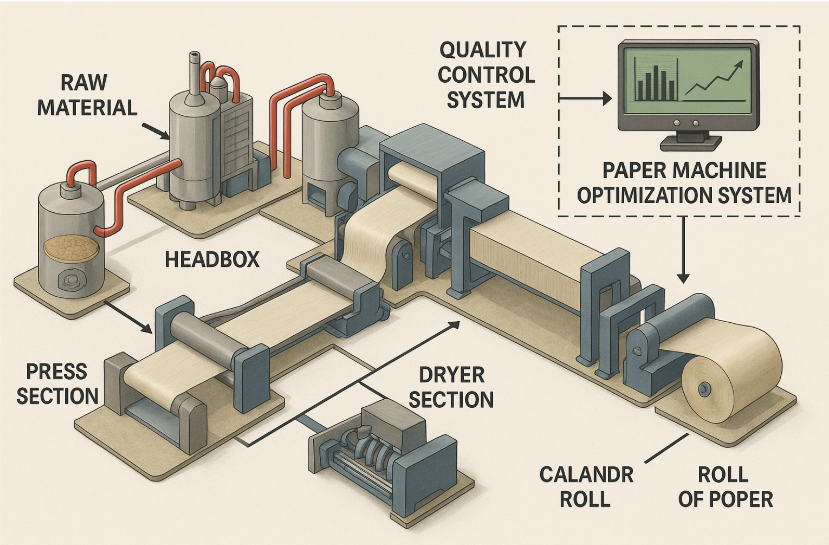

PMOPT- Paper machine optimization system

For the past nine years, TPW Industries LLP has focused on optimizing paper manufacturing by addressing hidden barriers that affect efficiency and profitability. In response to market pressures, the paper industry is restructuring its operations. To support this transition, TPW developed PMOpt—a system that enhances paper machine stability and product quality by optimizing control parameters through integration with QCS

CONCEPT

- PMOpt monitors final product quality, feed parameters, and resource capacity.

- Requires field instruments for effective process monitoring and control.

- Must be integrated with a modern control system.

- Supports integration with third-party packages.

- Existing discrete controls should be merged into PMOpt and then removed.

system architecture

The PMOpt package functions at the supervisory level, using real-time data and proprietary MPC algorithms to optimize paper production. It models various paper machine sections and integrates seamlessly with existing or third-party control systems. No machine modifications are required, as it enhances existing setups. The system can increase speed by up to 2 MPM per grade, ensuring rapid ROI. Through periodic analysis and optimization band reviews, it improves quality and output without the need for capacity upgrades or structural changes.

.png)

Pre-requisits

.png)

The PMOpt package requires monitoring and control of various vital parameters of the paper machine that are related to product quality. Key parameters and controls include:

- SR Box consistency monitoring & control for each street of the approach flow system

- Head Box level monitoring & control along with air blower capacity monitoring

- Head Box pressure and jet-wire ratio monitoring & control along with fan pump capacity monitoring for production optimization

- Online basis weight, moisture, and other parameter monitoring & control

- OPC connectivity to transfer instantaneous and scan average of basis weight, moisture, and other parameters, as well as 2-sigma values from the QCS to third-party systems

- Pressure screens and centric-cleaners pressure and differential pressure monitoring

- Steam and condensate monitoring and control with capacity monitoring to optimize production

- Relative humidity monitoring in the dryer sections

- Vacuum monitoring at various sections of the paper machine

- Machine chest consistency monitoring & control

Other parameters, wherever possible, can be connected to the PMOpt package for machine speed optimization. Parameters marked in red are mandatory, while others are optional but provide optimal control if implemented.

CASE STUDY

“We implemented this solution in a paper industry, successfully optimizing processes, improving operational efficiency, enhancing reliability, and delivering measurable business value, resulting in consistent performance improvements and sustainable growth.”

how pmopt enhanced production

The implementation of the PMOpt based recipe management the following points has been achieved:

- Increased production

- Reduce grade change recovery time

- Faster startup time

- Reduced Paper Breaks

- Increased speed through better speed control

.png)

Benefits

The implementation of the PMOpt based recipe management the quick grade change has been achieved. There is an increase in production from 832 MT to 871MT. The grade wise break-up is graphically shown in Fig-2. below. Total monetary gain is around Rs. 69 Lakhs. Also due to auto process control, operator’s intervention has been reduce and it has provided the easy of operation.